Valves

Valves are critical components in various industrial applications, responsible for controlling the flow of liquids, gases, or slurries through a pipe, duct, or other passageways. These devices are designed to regulate, direct, or control the flow of fluids by opening, closing, or partially obstructing the passage.

Key Types of Valves

Ball Valves

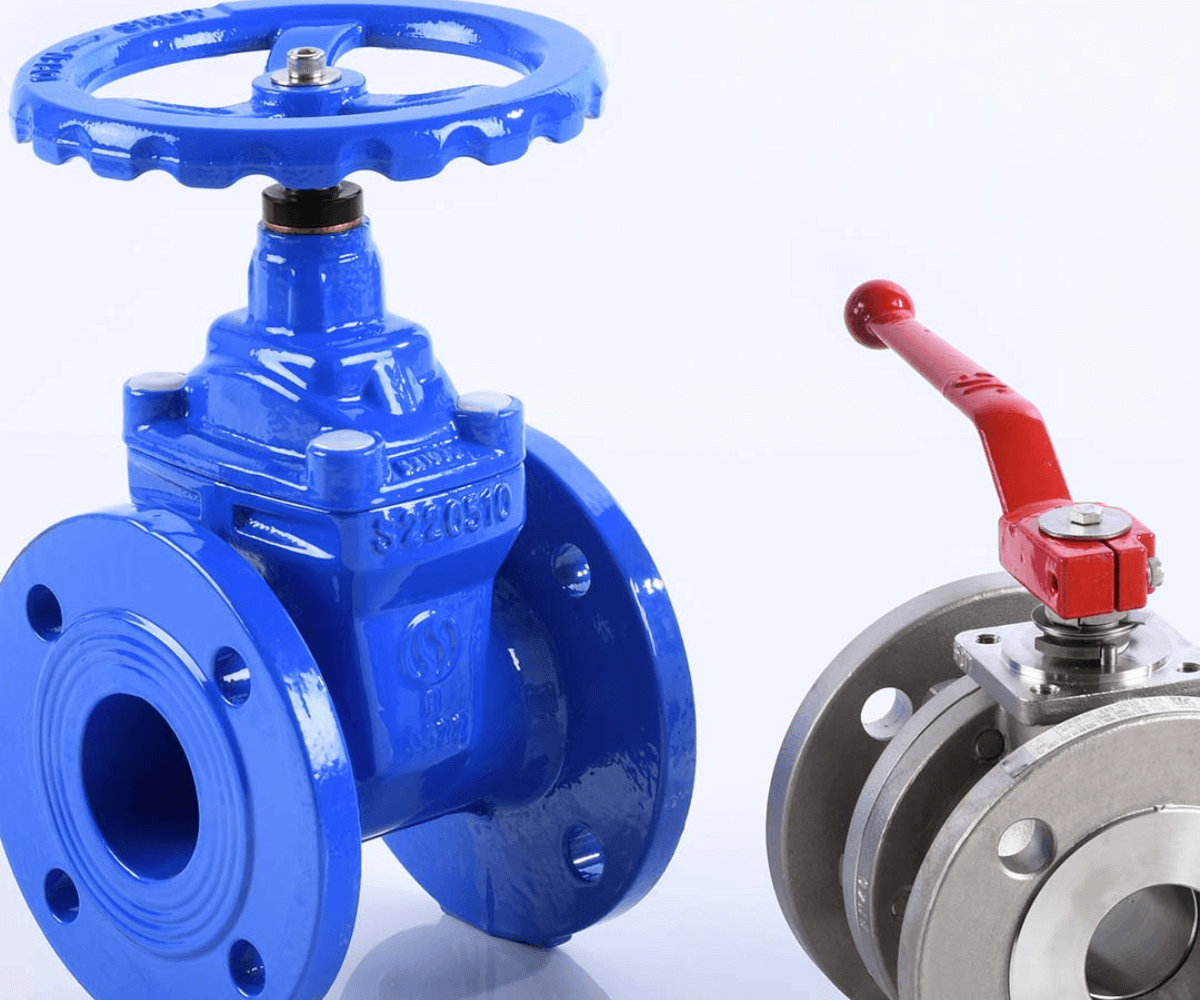

Ball valves are widely used for shutoff applications. They consist of a spherical disc that rotates to control the flow of fluid. Ball valves are known for their quick action and durability, making them suitable for a wide range of applications, including industrial, commercial, and residential systems.Gate Valves

Gate valves are used primarily for on/off control of flow. These valves have a wedge-shaped gate that moves up and down to allow or block fluid flow. They are commonly found in applications requiring a full, uninterrupted flow when open, such as in water systems, oil pipelines, and sewage treatment plants.Globe Valves

Globe valves are designed for regulating flow in a pipeline. They have a spherical body and an internal baffle that creates a narrow passage for fluid to flow through. These valves are ideal for throttling and are used in applications requiring precise flow control, such as in steam systems, cooling systems, and chemical processes.Check Valves

Check valves allow fluid to flow in only one direction and prevent backflow. They are essential for preventing reverse flow that could damage equipment or disrupt operations. Check valves are commonly used in pumps, compressors, and other systems where maintaining unidirectional flow is critical.Pressure Relief Valves

Pressure relief valves are safety devices designed to protect pressure vessels, pipes, or systems from overpressure. When the pressure exceeds a predetermined value, the valve opens to release excess pressure, ensuring the integrity of the system. These valves are commonly used in steam boilers, refrigeration systems, and chemical processing plants.Butterfly Valves

Butterfly valves use a disc that rotates within the valve body to regulate fluid flow. These valves are compact, lightweight, and provide quick operation, making them ideal for large-scale systems requiring reliable and efficient flow control, such as in water treatment plants, HVAC systems, and fire protection systems.Globe Valves

Globe valves are used for regulating flow and providing throttling capabilities. They have a spherical body shape, and an internal baffle controls the flow passage. Ideal for precise adjustments, these valves are used in systems requiring fine-tuned control, such as in heating, cooling, and chemical processing.Needle Valves

Needle valves provide very precise flow control due to their long, tapered needle-like stem. These valves are used in systems requiring exact flow adjustments, such as in gas lines, instrumentation systems, and laboratory setups.Solenoid Valves

Solenoid valves are electrically controlled valves used for controlling the flow of fluids or gases in automated systems. When an electrical current is passed through the solenoid coil, it causes the valve to open or close. These valves are essential in applications like irrigation systems, water treatment plants, and automated machinery.Ball Check Valves

Ball check valves are a variation of check valves, where a ball is used to block or allow fluid flow. These valves are typically used to prevent backflow and can be found in systems like pumps, drainage, and fluid transfer systems.

Key Applications of Valves

Industrial Applications

Valves are used extensively in industries like chemical, oil and gas, power generation, water treatment, and pharmaceuticals. They regulate fluid flow in pipelines, control temperature and pressure in reactors, and ensure safety in pressurized systems.Residential Applications

In residential systems, valves regulate water flow in plumbing systems, control gas flow for heating, and manage the flow of liquids in appliances such as washing machines and dishwashers.HVAC Systems

Valves are used in heating, ventilation, and air conditioning systems to regulate the flow of water or refrigerants, ensuring efficient operation of the system.Automotive Applications

In vehicles, valves are critical for controlling fuel flow, air intake, exhaust gases, and hydraulic systems. Engine control valves, fuel valves, and emission control valves are key components in modern automotive design.Food and Beverage Industry

In food and beverage production, valves help control the flow of liquids, powders, and gases. They play a crucial role in maintaining hygiene and precise flow control during production, bottling, and packaging.Pharmaceutical and Biotechnology

Valves in pharmaceutical manufacturing control the flow of ingredients and reactants in sterile conditions, ensuring product safety and consistency. Specialized valves are also used in processes like aseptic filling and mixing.Water Treatment Systems

Valves are integral to the distribution of water in municipal and industrial water treatment plants. They control flow to filtration units, regulate water pressure, and direct water to various treatment and distribution channels.

Benefits of Using Valves

Flow Control

Valves provide precise control over the flow of liquids, gases, and slurries, enabling systems to operate efficiently and maintain desired process parameters.Safety

Valves like pressure relief and check valves help prevent dangerous situations by controlling pressure and preventing backflow, enhancing safety in industrial operations.Automation

Electrically controlled valves like solenoid valves enable automated processes in various industries, reducing the need for manual intervention and improving system reliability.Energy Efficiency

Valves help optimize energy use by controlling flow and pressure, reducing waste and ensuring that equipment operates at its most efficient level.