Hydraulic Tools

Hydraulic tools utilize hydraulic power to perform heavy-duty tasks that would otherwise be difficult or impossible to achieve manually. These tools use pressurized hydraulic fluid to generate force, making them ideal for applications requiring high power and precision. Hydraulic tools are commonly used in construction, automotive repair, manufacturing, and other industries that demand high performance, reliability, and efficiency.

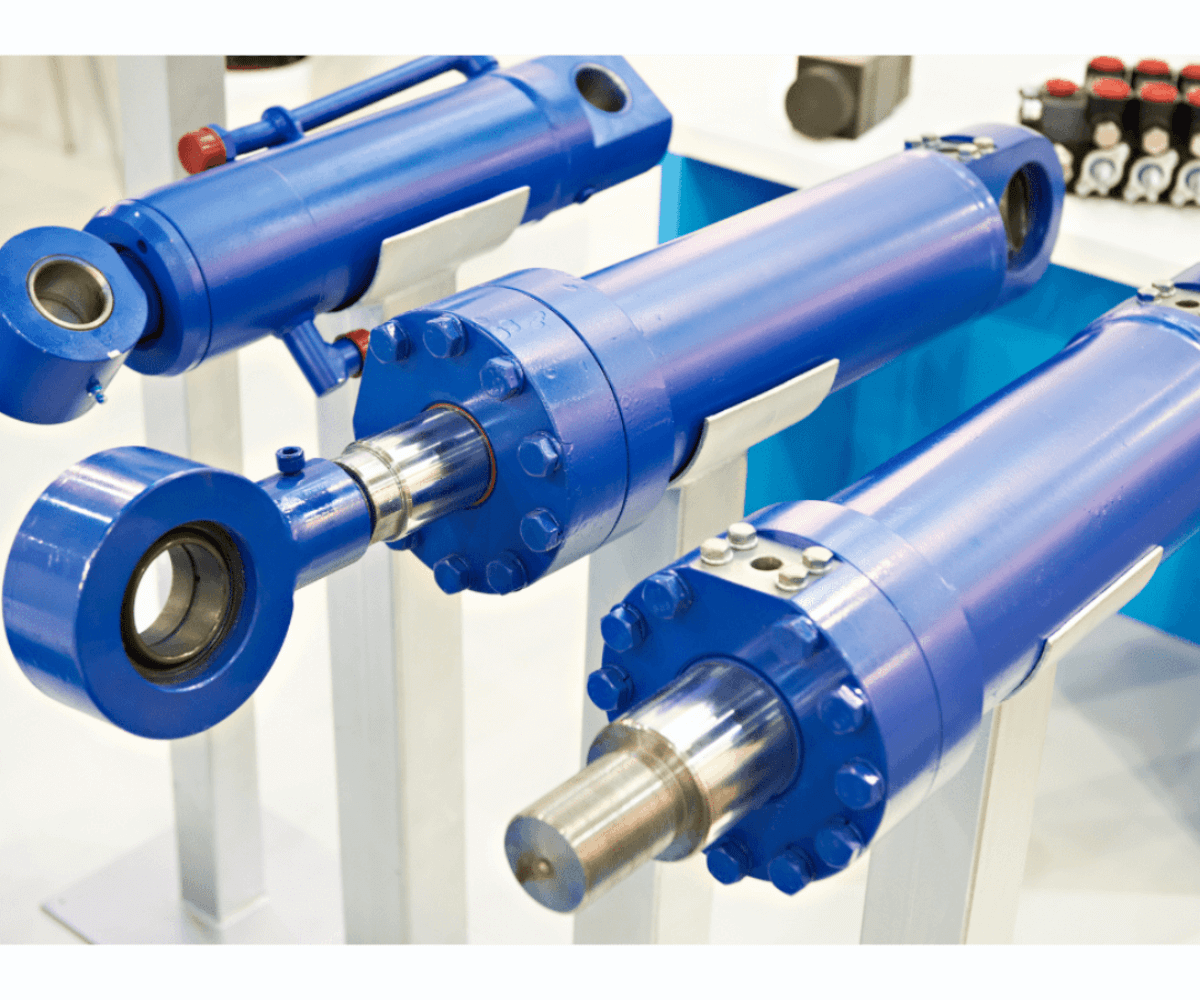

Key Types of Hydraulic Tools

Hydraulic Jacks

Hydraulic jacks are used to lift heavy loads, such as vehicles, machinery, or construction materials. By using hydraulic force, these jacks provide the necessary power to lift large objects safely and efficiently. They are available in various sizes, from small, portable models for automotive use to large industrial models capable of lifting tons of weight.Hydraulic Pumps

Hydraulic pumps are essential components that generate the hydraulic pressure required to power other hydraulic tools. These pumps convert mechanical energy into hydraulic energy by pressurizing fluid. They are used in various systems, including construction machinery, automotive lifts, and industrial presses.Hydraulic Hoses and Couplings

Hydraulic hoses and couplings are used to transport pressurized hydraulic fluid between components in a system. These hoses are designed to withstand high pressure and extreme temperatures while maintaining flexibility. Couplings ensure that the hoses connect securely and safely to various equipment, ensuring efficient power transmission.Hydraulic Torque Wrenches

Hydraulic torque wrenches are used to apply precise amounts of torque to bolts, nuts, and other fasteners. They are commonly used in industries such as construction, automotive, and oil and gas, where accurate torque settings are essential for ensuring safety and reliability. Hydraulic torque wrenches offer high torque output in a compact and easy-to-use form.Hydraulic Crimping Tools

Hydraulic crimping tools are used to attach connectors, lugs, and terminals to wires or cables. These tools provide the high force necessary to create a secure electrical connection, making them crucial in electrical and telecommunication industries. Hydraulic crimping tools are more efficient and provide better results than manual crimping tools, especially when working with large wires.Hydraulic Cutters

Hydraulic cutters are used to cut through tough materials such as metal, plastic, and reinforced cables. These tools are especially useful in emergency situations, such as rescue operations, or for cutting heavy-duty industrial materials. Hydraulic cutters provide increased cutting force, enabling them to handle tough cutting tasks effortlessly.Hydraulic Pullers

Hydraulic pullers are used to remove parts that are pressed or fitted into machinery, such as gears, bearings, and pulleys. These tools apply a controlled hydraulic force to safely and effectively remove components without causing damage to the surrounding equipment. They are commonly used in automotive, manufacturing, and maintenance operations.Hydraulic Presses

Hydraulic presses are used to apply a uniform force over a large area to shape, form, or bend materials. These presses are widely used in metalworking, plastics manufacturing, and even in automotive industries for tasks such as stamping, molding, and forming. Hydraulic presses provide significant force in a compact, manageable tool, allowing for efficient production processes.Hydraulic Demolition Tools

Hydraulic demolition tools, such as breakers, hammers, and crushers, are used to break down concrete, stone, and other hard materials during construction or demolition projects. These tools provide high-impact force that can break through tough surfaces, making them essential for construction and mining industries.Hydraulic Lifting Equipment

Hydraulic lifting equipment, such as lifts and hoists, are used to raise heavy loads. These tools use hydraulic pressure to lift materials in a controlled and safe manner. Hydraulic lifting systems are commonly used in warehouse operations, automotive repair, and heavy machinery maintenance.

Key Applications of Hydraulic Tools

Construction Industry

Hydraulic tools are indispensable in construction for tasks like lifting, cutting, demolition, and driving piles. Hydraulic jacks, presses, and breakers make construction projects more efficient, reducing manual labor and increasing safety.Automotive and Industrial Maintenance

Hydraulic tools are widely used in automotive workshops for tasks like lifting vehicles, crimping cables, and applying torque to fasteners. Hydraulic pumps, jacks, and torque wrenches streamline automotive repairs and maintenance.Oil and Gas Industry

In the oil and gas sector, hydraulic tools are used for wellhead maintenance, pipeline repair, and drilling operations. Hydraulic equipment such as torque wrenches, cutting tools, and lifting systems are essential for ensuring smooth operation and safety in this demanding industry.Manufacturing

Hydraulic tools are used in manufacturing for tasks like forming, shaping, and assembling parts. Hydraulic presses, crimpers, and jacks are essential tools for achieving high precision and efficiency in production lines.Rescue Operations

Hydraulic rescue tools, such as cutters, spreaders, and rams, are commonly used by emergency services during accidents and rescues. These tools help emergency responders free trapped individuals by cutting through metal and other debris.Mining

In mining, hydraulic tools are used to move heavy rocks, dig tunnels, and extract materials. Hydraulic jacks, shovels, and drills are crucial for working in harsh environments and improving operational efficiency.

Benefits of Using Hydraulic Tools

High Power Output

Hydraulic tools provide significant force in a small, portable form factor, allowing for high-performance results without the need for large, cumbersome equipment.Precision and Control

Hydraulic tools offer precise control over tasks like lifting, cutting, and tightening, ensuring that operations are carried out with accuracy and consistency.Durability

Hydraulic tools are designed to withstand harsh environments and heavy use. Their robust construction ensures long-term reliability, even under demanding conditions.Safety

Hydraulic tools reduce the need for manual labor, reducing the risk of operator injury. They provide a safe way to perform high-force tasks while minimizing physical strain.Efficiency

Hydraulic tools make tasks faster and easier by applying consistent force and automating complex processes, leading to higher productivity and reduced downtime.