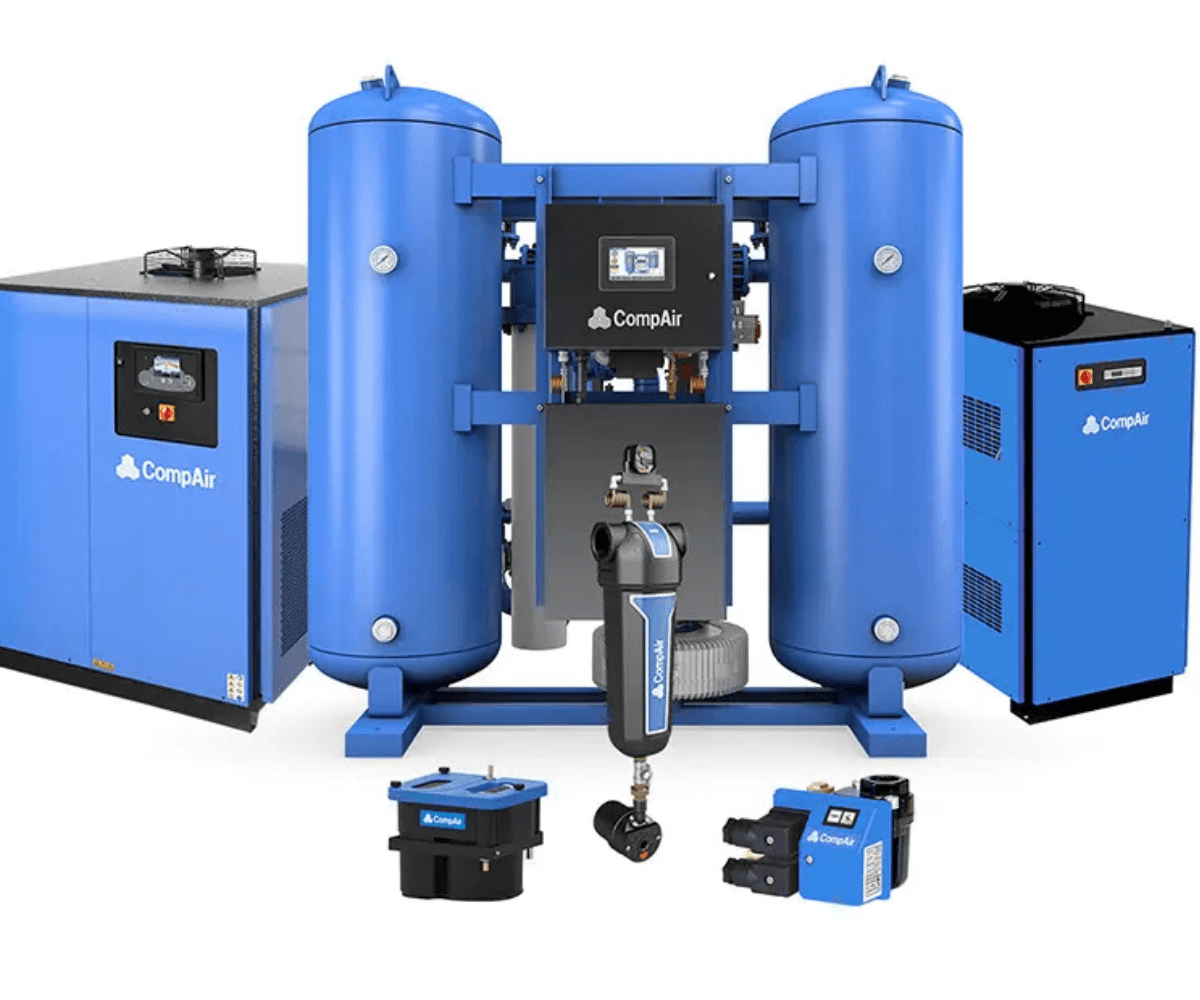

Compressed Air Treatment

Compressed Air Treatment products are essential components designed to improve the quality of compressed air systems by removing contaminants such as moisture, dirt, and oil. These products ensure that the compressed air is clean, dry, and safe for use in various industrial and commercial applications. Proper air treatment is crucial for protecting equipment, enhancing performance, and ensuring safe operation.

Key Products

Air Dryers

Air dryers are designed to remove moisture from compressed air. They are available in different types, including refrigerated, desiccant, and membrane dryers. By preventing moisture buildup, air dryers ensure that tools and equipment remain dry and functional, reducing the risk of corrosion and system damage.Air Filters

Air filters capture and remove dirt, dust, and other contaminants from the compressed air before it reaches the system or equipment. Proper filtration is essential for maintaining the integrity of pneumatic tools and preventing damage caused by particulates.Oil Water Separators

Oil water separators remove oil and water contaminants from the compressed air system. These units help in preventing the contamination of the environment and ensure that the air quality is safe for sensitive equipment.Pressure Regulators

Pressure regulators control and maintain a stable air pressure within the system. By ensuring that the air pressure remains within the optimal range, pressure regulators protect equipment from potential damage caused by excessive or insufficient pressure.Drain Traps

Drain traps are used to remove accumulated condensate (water, oil, and other fluids) from the compressed air system. By automating the removal of water and oil, these devices help in maintaining the efficiency and reliability of the compressor and downstream equipment.Desiccant Filters

Desiccant filters are used to absorb moisture and prevent water from entering the system. They are ideal for applications where the air must be kept dry to avoid corrosion and contamination of sensitive components or processes.Coalescing Filters

Coalescing filters are designed to remove oil and water droplets from compressed air. They work by combining tiny droplets into larger ones, which are then separated from the air stream. This ensures that the air is clean and free from harmful moisture and oil.Micro Filters

Micro filters are highly effective at removing small particles and contaminants from compressed air. These filters are ideal for applications requiring ultra-clean air, such as in food processing, pharmaceuticals, and electronics manufacturing.Activated Carbon Filters

Activated carbon filters remove oil vapors and other organic contaminants from compressed air. They provide an additional layer of protection to ensure that the compressed air is free of harmful substances that can affect sensitive equipment or processes.Silica Gel Dryers

Silica gel dryers are used to adsorb moisture from the air. These dryers are suitable for applications that require low dew points, and they are often used in processes that demand dry air to ensure optimal performance.Air Line Lubricators

Air line lubricators introduce a controlled amount of oil into the compressed air system to lubricate pneumatic tools and machinery. They help reduce friction, prevent wear, and extend the life of equipment by ensuring smooth operation.Water Separators

Water separators remove excess water from compressed air to prevent moisture-related issues such as rusting, freezing, and equipment malfunction. They are essential for systems that operate in humid or high-moisture environments.Condensate Management Systems

Condensate management systems are designed to efficiently manage the condensate produced in compressed air systems. These systems help in the removal and treatment of moisture, ensuring that the air remains dry and the system stays clean.Air Flow Meters

Air flow meters measure the flow rate of compressed air in the system. By accurately monitoring the flow, these meters help in optimizing the performance of the system and ensuring that the right amount of air is delivered to various components.Particle Separators

Particle separators remove fine dust and other small particles from the compressed air. They prevent particles from entering sensitive equipment, protecting components and ensuring a consistent air quality.

Applications

- Manufacturing: Compressed air treatment products ensure clean, dry air for powering pneumatic tools, machinery, and equipment in manufacturing processes.

- Automotive Industry: In the automotive industry, these products protect air-powered tools, spray booths, and other equipment from damage caused by moisture and contaminants.

- Pharmaceuticals & Food Processing: In industries where clean air is critical, such as pharmaceuticals and food processing, compressed air treatment ensures that the air meets stringent quality standards.

- Electronics: For electronics manufacturing, where precision and cleanliness are paramount, compressed air treatment products remove contaminants that could affect the quality and performance of delicate components.

- Oil and Gas: In oil and gas operations, air treatment products help protect equipment from contaminants that can cause corrosion and malfunction, ensuring efficient and reliable operations.