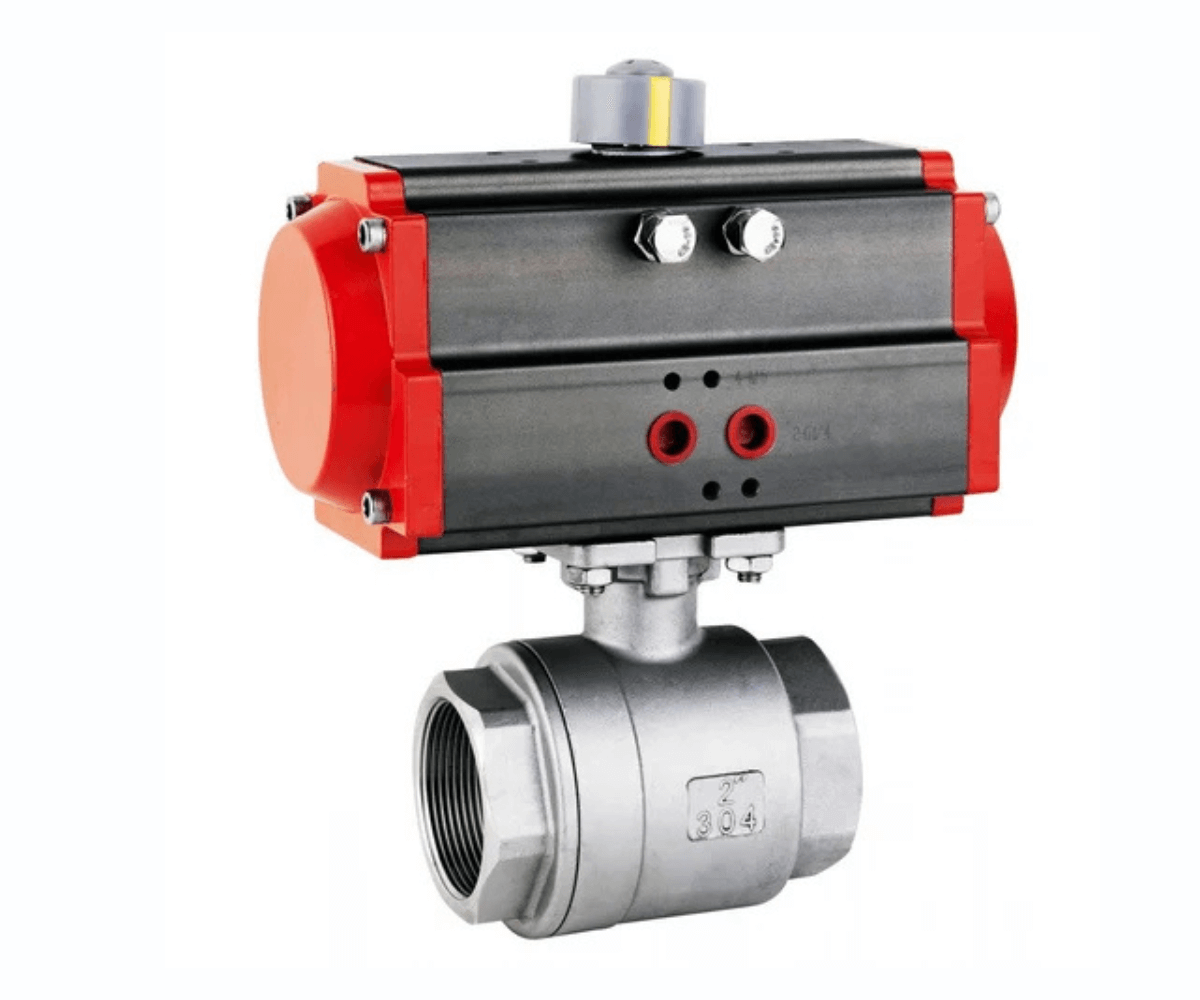

Actuated Ball Valves

Actuated Ball Valves are designed to provide efficient and reliable fluid flow control in various industrial applications. These valves combine the functionality of a ball valve with an actuator, enabling automated and precise regulation of the flow of gases, liquids, or slurries. Ideal for systems requiring frequent operation, they are highly used in industries such as chemical processing, water treatment, and HVAC systems.

Key Features

- Automated Operation: Paired with an actuator, allowing for remote or automated control of fluid flow without manual intervention.

- Quick and Precise Response: Fast-acting with accurate flow control, reducing operational delays and improving system efficiency.

- High Durability: Built with corrosion-resistant materials such as stainless steel, ensuring long-lasting performance even in harsh environments.

- Versatile Design: Available in a wide range of sizes, materials, and configurations to suit different system requirements and industry standards.

- Leak-Free Performance: Features a tight seal, ensuring minimal risk of leakage and preventing wastage of fluids or gases.

- Compact and Robust: Space-efficient design suitable for installations in tight spaces, while offering high reliability and performance.

- High Flow Rate: Capable of handling high flow rates, making them ideal for large-scale industrial operations.

- Temperature and Pressure Tolerance: Suitable for high-pressure and high-temperature environments, ensuring safe operation in demanding applications.

Applications

- Chemical and Petrochemical Industries: Ideal for controlling the flow of various chemicals and petrochemical products, where precise flow control and safety are critical.

- Water and Wastewater Treatment: Used to regulate the flow of water or wastewater, helping maintain consistent flow rates in treatment plants and pipelines.

- Oil and Gas Industry: Perfect for managing the flow of oil, gas, and other related fluids, providing high efficiency in exploration, production, and distribution systems.

- HVAC Systems: Employed in heating, ventilation, and air conditioning systems to control the flow of water, air, or steam.

- Food and Beverage Processing: Used for managing the flow of liquids or slurries in food processing plants, ensuring safety and hygiene compliance.

- Power Generation: Essential for controlling the flow of steam, water, or gases in power plants, ensuring smooth and controlled operation.

- Pharmaceuticals: Used in pharmaceutical manufacturing processes where precise flow regulation is crucial for the production of high-quality products.