Pneumatic Cylinders

Pneumatic cylinders are devices that use compressed air to generate linear motion. These cylinders are integral components in numerous industries for their ability to deliver force, precision, and reliability in automation and machinery operations. By utilizing the force of compressed air, pneumatic cylinders are ideal for applications that require controlled, repetitive motion, including lifting, pushing, pulling, and positioning tasks.

Types of Pneumatic Cylinders

Single-Acting Pneumatic Cylinders

Single-acting cylinders use compressed air to drive the piston in one direction, with a spring returning the piston to its original position. They are used in applications where motion is only required in one direction, such as in push or pull tasks, and are cost-effective for simple applications.Double-Acting Pneumatic Cylinders

Double-acting cylinders utilize compressed air to drive the piston in both directions. This type of cylinder offers more power and flexibility, making it suitable for tasks requiring force in both extension and retraction. Double-acting cylinders are commonly used in industrial automation and material handling applications.Tie Rod Pneumatic Cylinders

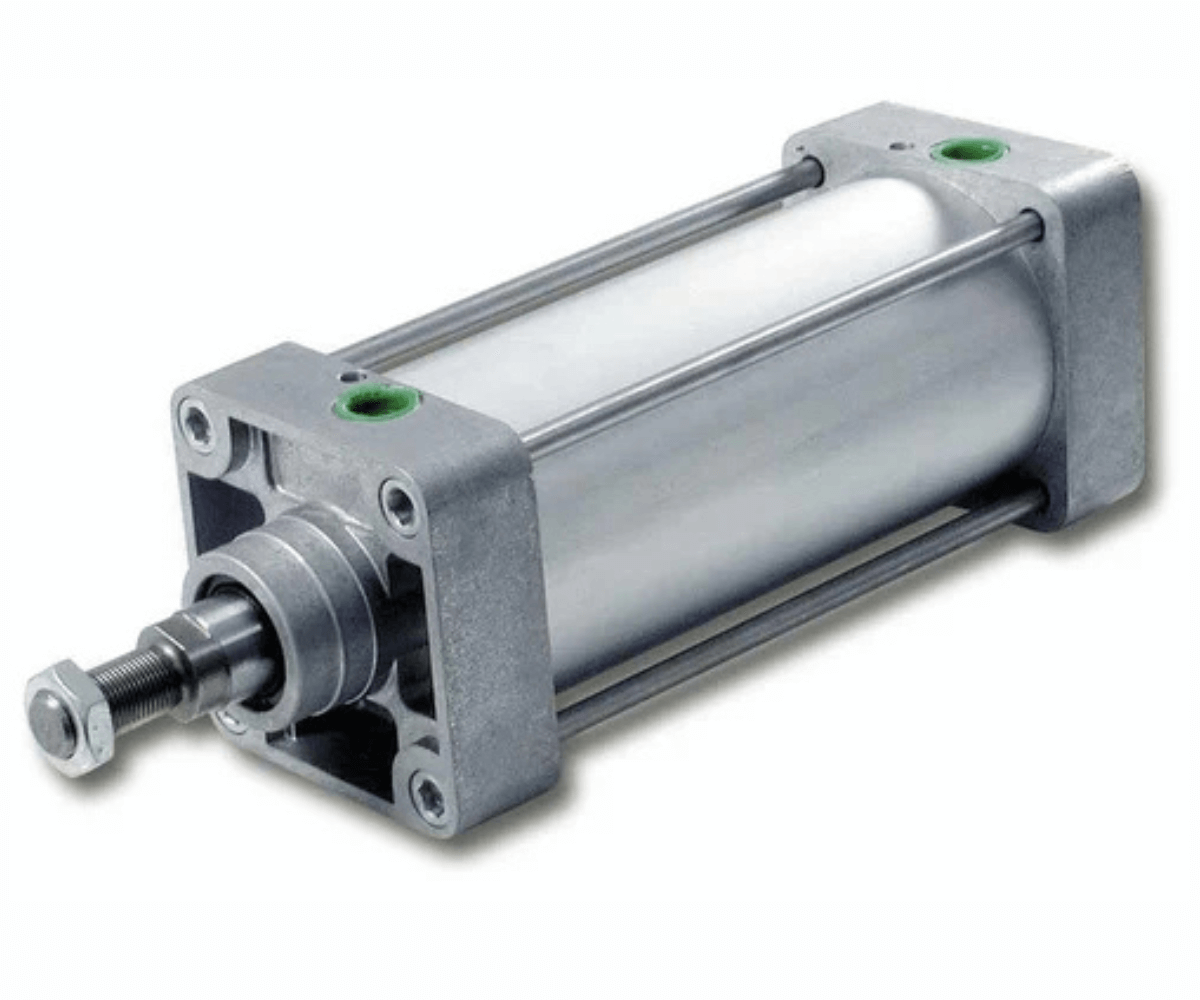

Tie rod cylinders are designed with external rods that hold the cylinder together, providing durability and ease of maintenance. They are ideal for high-force applications and are commonly used in heavy-duty industrial machinery and automation systems.Compact Pneumatic Cylinders

Compact cylinders, also known as mini cylinders, are designed for space-constrained environments where traditional cylinders may not fit. Despite their smaller size, they offer high force and are typically used in small automation equipment, robotics, and precision assembly.Rodless Pneumatic Cylinders

Rodless cylinders feature a unique design where the piston does not have an external rod, allowing the piston to move within the cylinder without external attachments. This design provides a more compact solution, suitable for limited space and applications requiring longer strokes or smooth continuous motion.Round Body Pneumatic Cylinders

Round body cylinders have a cylindrical design and are typically lightweight and versatile. They are used in applications where compact size and smooth motion are required, such as in packaging machines, conveyors, and automated systems.Non-Rotating Pneumatic Cylinders

Non-rotating cylinders are specifically designed to prevent the piston rod from rotating during its motion. This feature ensures precise linear movement, making them suitable for applications where rotation of the piston rod could cause operational issues, such as in positioning and material handling systems.

Applications of Pneumatic Cylinders

- Industrial Automation: Pneumatic cylinders play a crucial role in factory automation, controlling the movement of robotic arms, conveyors, and other machinery.

- Material Handling: Pneumatic cylinders are used in loading, unloading, and transporting materials on production lines and assembly systems.

- Packaging Machines: In the packaging industry, pneumatic cylinders are used for tasks such as filling, sealing, and labeling.

- Construction Equipment: Pneumatic cylinders are used in heavy equipment for controlling movements such as lifting and extending arms in cranes and excavators.

- Textile Industry: Pneumatic cylinders are used in textile machinery for operations like weaving, spinning, and cutting fabric.

- Automation in Assembly Lines: Pneumatic cylinders move parts along assembly lines in the automotive and electronics industries, ensuring accurate and fast operations.

- Valves and Fluid Control: Pneumatic cylinders are often used for opening and closing valves in fluid control systems, ensuring smooth and controlled operations.